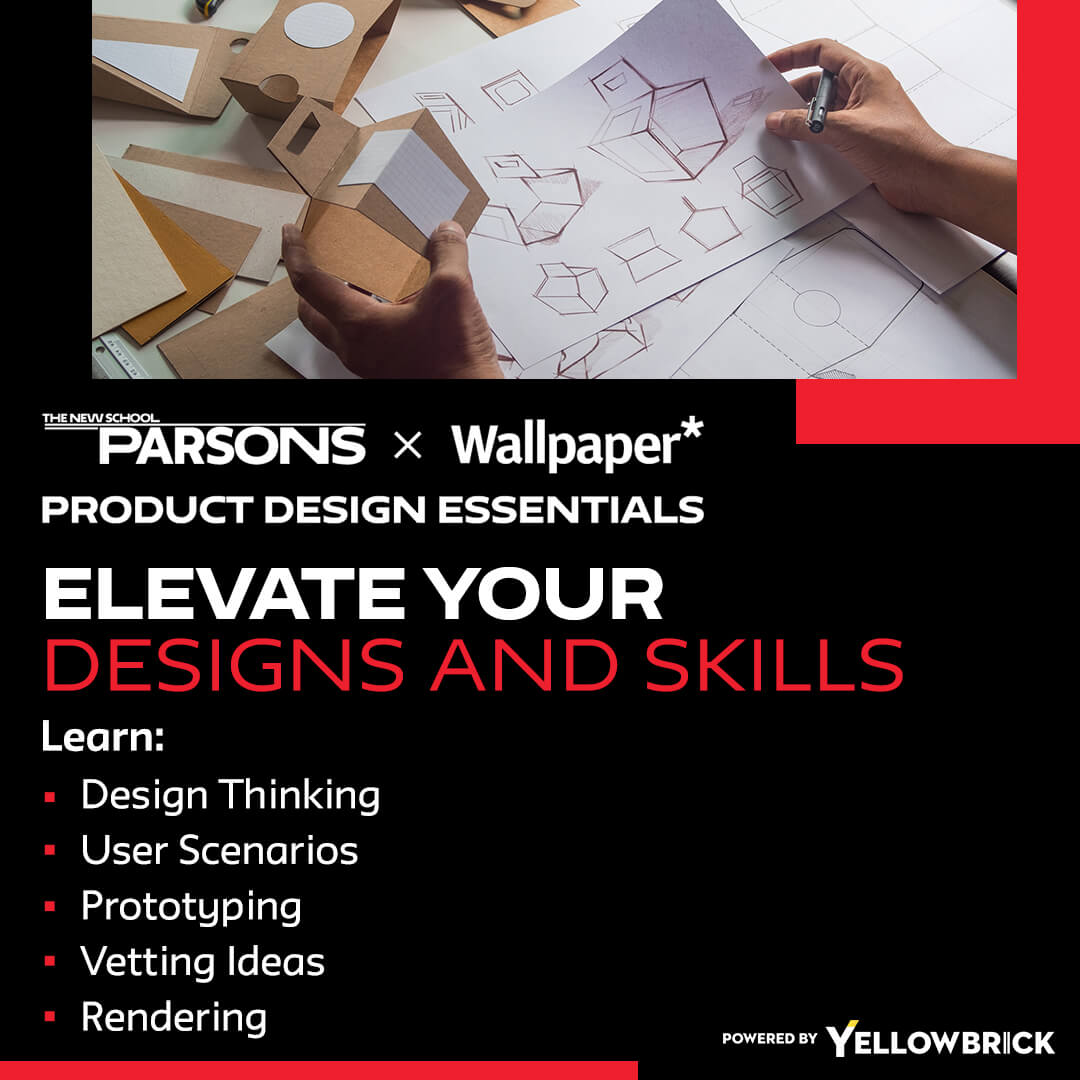

Modeling: A Key Task in Product Design

Often, when designers use the word modeling, and if you were to look up an industrial design model, you would see a product that really looks like the real thing. So if you looked at the model of a shoe, a model of a surgical tool, or a model of a bandage, it’s just going to look like that specific product that represents the product design concept.

But that model in what we call the high-fidelity state is not really for testing. That model is to show what we call a proof of concept or to illustrate our final design intent to help others visualize the concept. But before we ever get to that model, we’re doing all sorts of Frankenstein modeling or low-fidelity models, because we’re just trying to figure this idea out. So, there may be several steps that lead to a satisfying end result.

If we never made a drone before, we’re trying to figure out how we can pull together a drone. You might buy existing products that work similarly, take them apart, and reverse engineer them to try to understand from a product development standpoint how they work, how they fit together, and how the pieces fit. You might be taking measurements or looking at the circuits.

But you’re really trying to understand the design from existing products, and some of these things can be almost exactly what you want to create. At other times, though, the design may be very different. But we’re trying to look for those influences and inspiration from analogs. Then we’ll pull that design together into functional or semi-functional prototypes where we’re just testing these ideas. For prototyping for designers, it really is about the inquiry of trying to test hypotheses about how things might work. This process is similar to what you might learn from a professional product design education.

Designing products from models is about aesthetics. So, sometimes we’re making form prototypes where we’re trying to understand how things should look or feel in the hand or while in use. Sometimes we’re experimenting with different materials on an object. We might want to see how one material behaves versus another. That can range from a fit in the hand to how it feels to your skin, but also it includes functionally pertaining to how these things work.

If you had something that had to spin or hinge or had to be very strong, you would want to test it to see if that material and that form factor or that shape would actually be able to do what you want it to do. You can learn more about this process by getting an online product design education.