Is 3D Printing the Best Option for Product Design Samples?

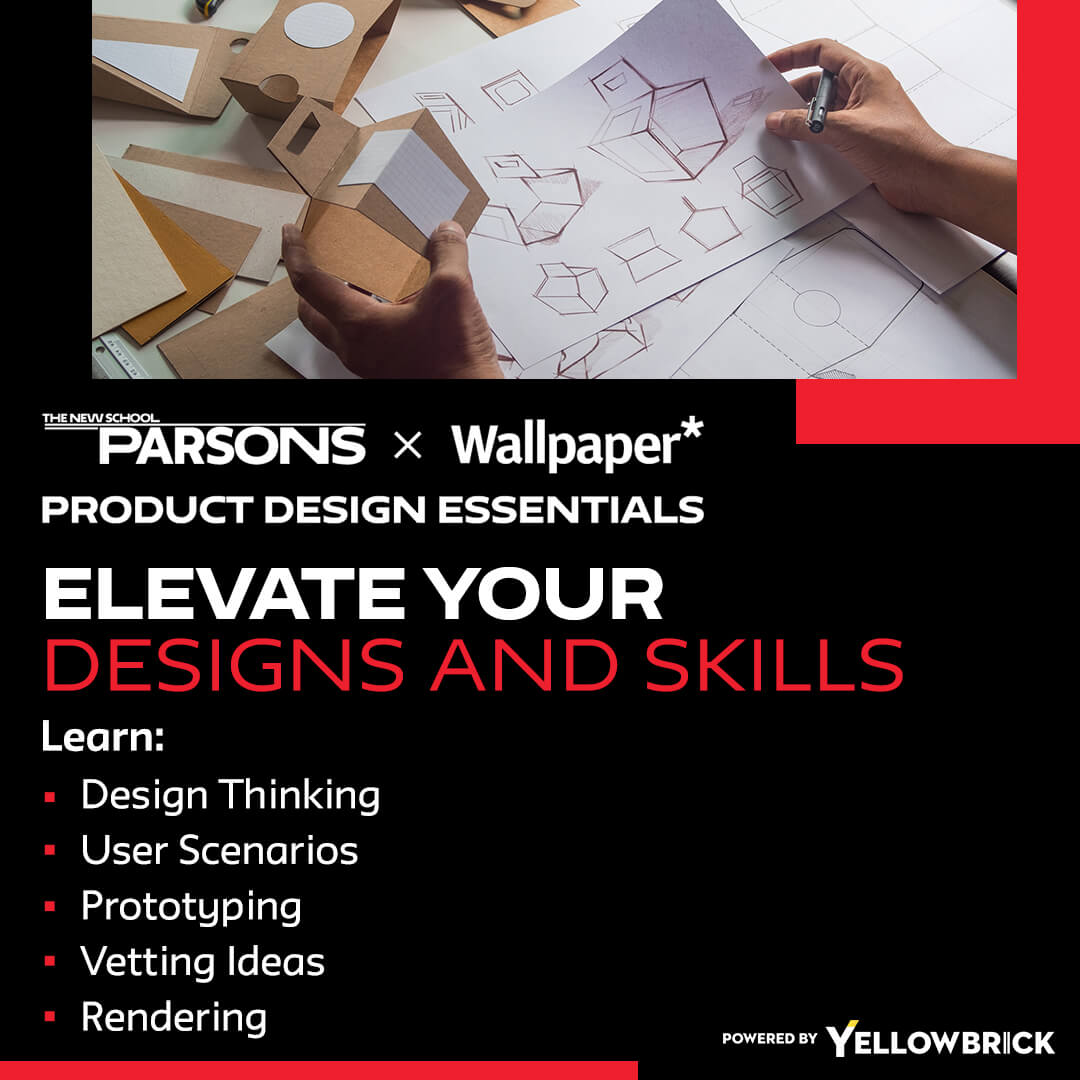

Prototyping is an essential part of our job, and it is not always what we all think about. Prototyping doesn’t necessarily require a machine or a 3D printer. I always tell my team that the first rapid prototyping machine they must use in their project is a printer. It is effective because you start designing on the screen, which can be very challenging. It’s a challenge because as soon as you get into CAD, you sometimes keep the notion of proportion, but you lose the notion of scale.

For example, I have had designers repeatedly create 3D printing. The day they take it out of the machine, they look at it and say, oh, my god, this is big! It is for such reasons that a simple print is actually a great way to prototype your project rapidly. As you get into your process and refine it, maybe you will decide to cut and form the shape. Based on the print you have done, maybe you get to a point where you’re going to 3D print. It means in particular situations, 3D printing can still be a necessity.

Usually, in 3D printing, you might prefer to keep it maybe not to the last stage but the later stage of the product development process. There is a good reason behind this claim. It’s when you have already refined your design quite a lot, and you’re nitpicking the proportion and specific detail. In this case, you really want to make sure that your surface transition is proper and so forth. These are some of the fundamentals everyone in product design education must learn. Also, it must include online product design education.

When I speak about 3D printing, that’s 3D printing in plastic. We also do 3D printing in metal, which is slightly different. It is different because we don’t need metal to evaluate or shape an interface. When we use 3D printing in metal, we use what we call DMLS. It is usually to print a production part, which makes it very expensive. In such cases, it becomes rare.

We have one line of products in which their production is of that approach, but they may all cost you almost as much as it costs. It’s a little bit specific and for a particular market, and it’s also interesting. Once you are comfortable with all the plastic 3D printing technologies that are available, making that last leap to print in production is not that difficult. It’s just one more step.